Polestar has published the first Life Cycle Assessment (LCA) for Polestar 4. The LCA reveals that Polestar 4 has the lowest carbon footprint of all Polestar cars to date – as low as 19.4 tonnes of CO2e at launch.

Polestar 4 is produced in Geely Holdings’ SEA factory in Hangzhou Bay, China, which combines green electricity that carries the I-REC hydro power certificate, with photovoltaic electricity from the roof of the plant. A higher use of low-carbon aluminium from smelters using hydropower electricity helps reduce the climate impact further. In addition, data regarding the share of recycled aluminium has been included in the assessment for the first time.

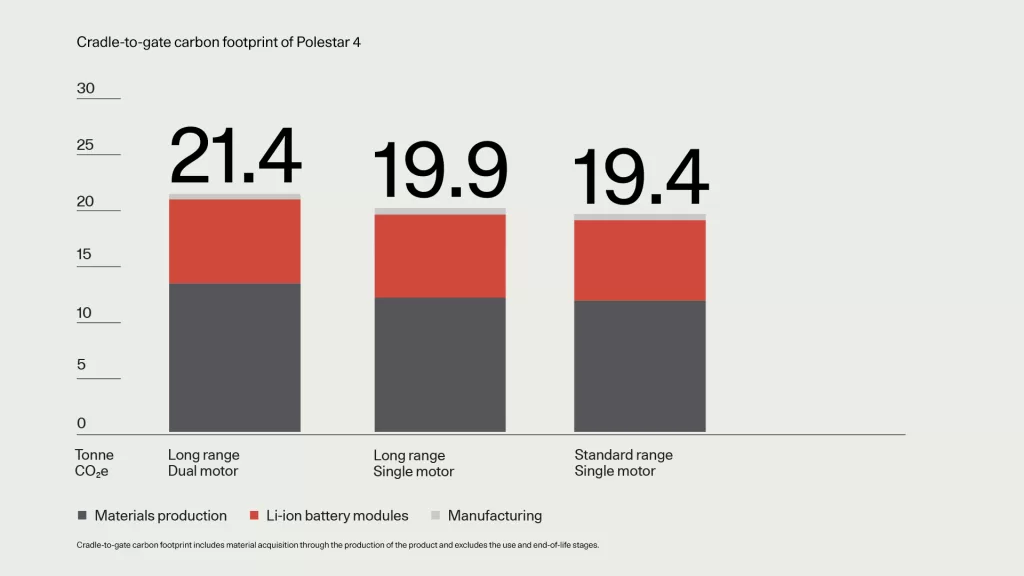

Available initially in China, the Polestar 4 Standard range Single motor comes with a carbon footprint of 19.4 tCO2e. The Long range Single motor version has a carbon footprint of 19.9 tCO2e, while the Long range Dual motor has one of 21.4 tCO2e. Aluminium represents 23-24% of the carbon footprint, while steel and iron constitute 20%, and battery modules account for the highest share of the carbon footprint of materials production and refining at 36-40%.

Fredrika Klarén, Head of Sustainability at Polestar, says: “To support our net zero goal, we set carbon budgets for all our cars. Throughout the product development of Polestar 4, its carbon budget has influenced everything from material choices to factory energy sources. Sharing the LCA enables us to show that we can strive for net zero – one tonne of CO2e at a time.”

Polestar publishes full details of the carbon footprint of all its models. The Swedish EV-maker believes the car industry should be a driving force in the shift to sustainable mobility, and that transparency is a key enabler.

Polestar’s LCAs, published since 2020, consider a range of factors in a car’s life cycle, from supply to manufacture and recycling, and summarise the climate impact in one easily understood number. This enables consumers to make quick and educated decisions when buying a car. The LCA figures stated in this release disclose the cars’ cradle-to-gate carbon footprint which includes material acquisition through the production of the product and excludes the use and end-of-life stages.