Making improvements with agility in the two months since missing Suzuka

The liquid hydrogen-powered Corolla was scheduled to compete for the first time at Round 1 Suzuka Super Taikyu 5 Hours Race held on March 18 and 19. However, during a private test run at Fuji International Speedway on March 8, a vehicle fire occurred due to a hydrogen leak from a gaseous hydrogen pipe in the engine compartment. As the vehicle could not be recovered in time, Toyota was forced to abandon the race.

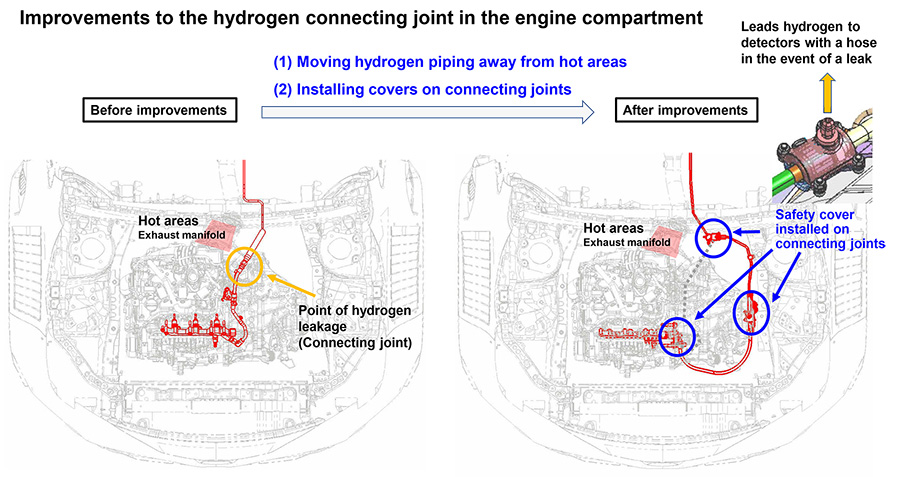

In the two months since missing Suzuka, the design of the hydrogen piping that caused the vehicle fire has been changed, with safety as the highest priority. These changes included (1) moving the hydrogen piping away from hot areas, and (2) installing safety covers on the hydrogen piping joints to prevent loosening and to catch and lead hydrogen to detectors in the event of a leak.

We have also succeeded in reducing the vehicle weight by over 50 kg over the past two months, leading to it exceeding the lap times of the hydrogen engine-equipped Corolla when it first competed in May 2021 using gaseous hydrogen fuel.

We have continued development and made improvements with agility through our motorsports activities with the support of our many partners in taking on this challenge, and this has made it possible for us to enter the Fuji 24 Hours Race. Improvements to hydrogen piping in the engine compartment

Improvements to hydrogen piping in the engine compartment

The challenge of liquid hydrogen

A portion of the liquid hydrogen being used in the hydrogen engine-equipped Corolla is lignite-derived hydrogen produced and transported from Australia in February 2022 by the Suiso Frontier liquid hydrogen carrier built by Kawasaki Heavy Industries, Ltd. (KHI) as part of the HySTRA*1 project.

The mobile liquid hydrogen station that will be used at the circuit was jointly developed by Iwatani Corporation and Toyota Motor Corporation. By using liquid hydrogen as fuel, equipment that was previously necessary to produce compressed gaseous hydrogen, such as compressors and pre-coolers for cooling hydrogen are no longer needed. As a result, the required station installation area can be a quarter the size of that for gaseous hydrogen stations, and fuel can be refilled in the pit area in the same way as for gasoline-powered vehicles. In addition, since there is no longer the need to pressurize when filling, multiple vehicles can be filled in succession.

The vehicle’s fuel supply system has been changed to a liquid hydrogen system in conjunction with the change from gaseous to liquid hydrogen. However, the engine itself is the same engine as when the vehicle was running on gaseous hydrogen.

Since the energy density per volume is increased by changing the fuel to liquid hydrogen, the cruising range has been doubled with the same filling time as before, approximately 1.5 minutes*2. We will strive to further improve engine performance, cruising range, and filling time throughout the year.

However, liquid hydrogen must be kept at temperatures lower than -253℃ during filling and storage. This poses unique challenges in areas such as developing fuel pump technology that can function in a low-temperature environment, preventing hydrogen from naturally evaporating from the tanks, and establishing regulations for vehicle-mounted hydrogen tanks. We will continue to work on overcoming these challenges with the cooperation of our partners in the areas of producing, transporting, and using hydrogen.

Both gaseous and liquid hydrogen have unique advantages and challenges, with gaseous hydrogen having the advantage of having a simpler system configuration. Toyota will continue to focus on developing both gaseous and liquid hydrogen to increase fuel supply options and make the most of their unique characteristics.

| Advantages of Liquid Hydrogen | Challenges with Liquid Hydrogen |

|---|---|

| Increased energy density and cruising range | Must be kept at temperatures lower than -253℃ |

| Smaller hydrogen stations (can be filled in the pit) | Preventing hydrogen from evaporating due to heat in the tank |

| Doesn’t need to be pressurized, allowing for multiple vehicles to be refilled in succession | Fuel pump technology that can function at -253℃ |

Starting joint research with universities to further reduce the weight of hydrogen engines

Toyota is able to race in this year’s Fuji 24 Hours Race with the liquid hydrogen-powered Corolla thanks to the cooperation of its many partners. We will continue to conduct joint research with Kyoto University, the University of Tokyo, and Waseda University on technologies to reduce the weight of the engines and the size of liquid hydrogen systems in order to create ever-better cars going forward.

| Joint Research Technology | University |

|---|---|

| Superconducting motor technology for automotive use liquid hydrogen pumps | Kyoto University, University of Tokyo, Waseda University |

| Centrifugal pump technology for automotive use liquid hydrogen | Waseda University |

Toyota will continue to work on further efforts with its partners, including not only corporations and local governments but universities as well, to realize a carbon-neutral society.

It will also continue to work with its partners to increase options based on its multi-pathway approach to meet the needs of customers around the world.